3D texturing is revolutionizing the way of metal surface finish, offering remarkable improvements in tribological properties. By reducing friction, it enhances wear resistance and ensures optimal lubrication, leading to superior performance in various applications. Studies highlight its effectiveness:

- Hao et al. demonstrated that surface texturing on rotor-bearing systems reduced vibrations, improving dynamic stability.

- Wei et al. observed a 4–7% reduction in friction under dry conditions and up to 60.3% under lubrication on laser-textured bearing steel.

- Cho and Choi reported a significant drop in the coefficient of friction from 0.26 to 0.092 on textured AISI 1045 steel surfaces.

These advancements showcase how 3D texturing addresses challenges in tribology, making it a game-changer for metal surface finish.

Key Takeaways

- 3D texturing lowers friction on metal, improving how things work.

- It makes parts last longer and cuts down repair costs.

- Industries can design surfaces for special uses, making them better-looking and useful.

- 3D texturing helps the environment by using less waste and energy.

- Tools like laser texturing make surfaces exact, great for top industries.

What Is 3D Texturing?

Definition and Overview

3D texturing refers to the process of creating detailed patterns and textures on a surface to enhance its physical and visual properties. Unlike traditional surface finishing, which often focuses on smoothness, 3D texturing introduces micro- or nano-scale patterns that improve functionality and aesthetics. This approach is widely used in industries such as automotive, aerospace, and consumer goods, where textured surfaces can optimize performance and design.

Biomimetic texturing, inspired by natural patterns like those found on lotus leaves or shark skin, has gained significant attention. These designs replicate nature’s efficiency, offering benefits such as reduced drag or improved grip. By combining science and creativity, 3D texturing transforms ordinary surfaces into high-performance materials.

The Process of 3D Texturing

Techniques in Surface Texturing

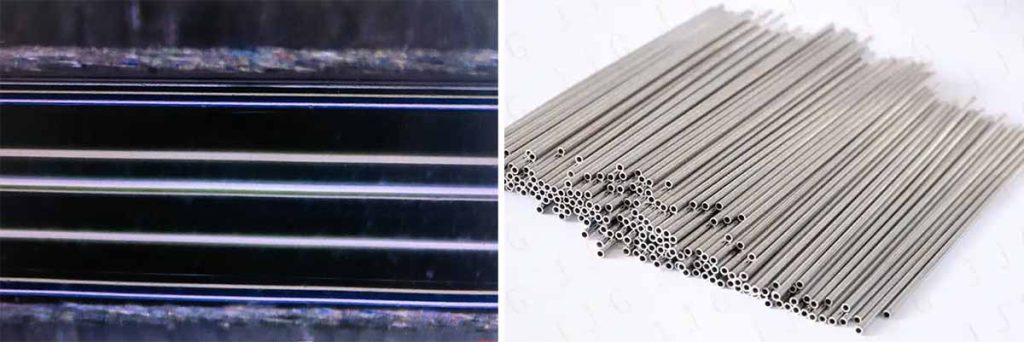

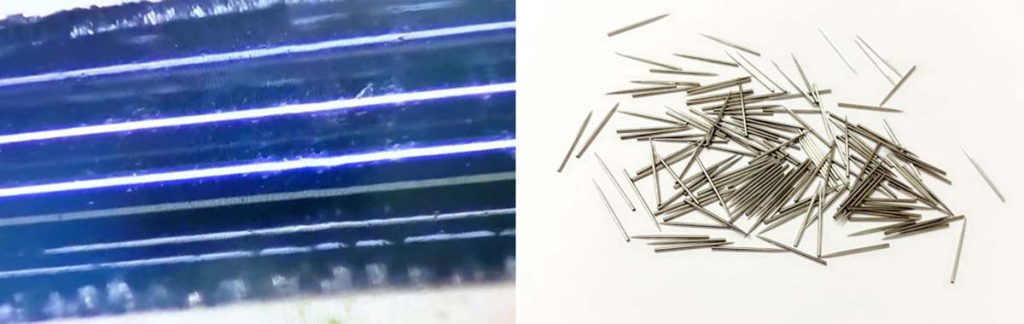

Surface texturing techniques vary depending on the desired outcome and material. Laser surface texturing is one of the most advanced methods, using laser beams to create precise patterns. This technique allows for unparalleled control over texture depth and density, making it ideal for applications requiring high precision. Other methods include chemical etching, mechanical engraving, and additive manufacturing, each offering unique advantages for specific use cases.

Tools and Technologies for 3D Texturing

Modern tools and technologies have revolutionized 3D texturing. Procedural texturing techniques generate realistic textures through algorithms, enabling faster creation of complex surfaces. Laser surface texturing remains a cornerstone, offering precision and consistency. Additionally, AI and machine learning tools are automating repetitive tasks, predicting optimal surface textures, and enhancing workflow efficiency. These advancements empower designers to focus on creativity while ensuring high-quality results.

Key Features of 3D Textured Surfaces

3D textured surfaces stand out due to their unique features. They enhance aesthetics and branding by allowing control over surface finishes, creating visually appealing products. Improved ergonomics and functionality make them ideal for grips and handles. Customization enables tailored finishes for diverse applications, supporting mass production with precision. Furthermore, biomimetic texturing pushes the boundaries of design by mimicking nature’s efficiency. These features make textured metal surfaces indispensable in modern manufacturing.

The Importance of Metal Surface Finish

Role in Performance and Durability

Impact on Friction and Wear

Metal surface finish plays a critical role in determining the friction and wear performance of engineering components. Surface roughness directly influences how materials interact under motion. Smoother surfaces reduce friction, which is essential for applications like bearings and gears. This reduction minimizes energy loss and enhances efficiency. Conversely, rough surface texture increases friction, leading to higher wear rates and potential system failures. In high-performance environments, such as aerospace, controlled surface texturing ensures reliability under repeated stress. By optimizing surface properties, engineers can significantly improve the lifespan and functionality of components.

Influence on Material Longevity

The longevity of materials depends heavily on their surface finish. Surfaces that are too rough are more prone to abrasive wear, while smoother surfaces resist wear and fatigue better. A well-controlled roughness profile prevents the development of cracks under stress, improving fatigue strength. This is particularly important in industries where components face extreme conditions, such as high temperatures or heavy loads. Textured surfaces designed with precision can extend service life by reducing wear and maintaining structural integrity over time.

Challenges with Traditional Surface Finishing

Traditional surface finishing methods often struggle to meet the demands of modern engineering. Techniques like grinding and polishing may lack the precision required for advanced applications. These methods can also result in inconsistent finishes, leading to variations in friction and wear performance. Additionally, traditional approaches may not support the customization needed for specific properties, limiting their effectiveness in industries like automotive and aerospace. The inability to achieve consistent results often increases maintenance costs and reduces overall efficiency.

Precision in Modern Applications

Modern applications demand unparalleled precision in surface texturing. Industries such as medical devices, electronics, and aerospace require surfaces that meet exact specifications to ensure optimal performance. For example, implants and surgical tools rely on precise surface properties to enhance biocompatibility and reduce wear. Similarly, electronic components benefit from textured surfaces that improve heat dissipation and durability. Advanced technologies like laser surface texturing enable manufacturers to achieve this level of precision, ensuring consistent results across large-scale production.

How 3D Texturing Enhances Tribological Properties?

Reduction in Friction

3D texturing significantly improves frictional performance by reducing the coefficient of friction on metal surfaces. This reduction occurs due to the introduction of micro-dimples and patterns that minimize the effective contact area between surfaces. Studies have shown that surface texturing achieved through electrochemical micromachining can reduce friction by 4–7% under dry conditions and up to 60.3% under lubricated conditions. These textures enhance dynamic stability and reduce vibrations, making them ideal for tribological systems in high-performance applications.

The hydrodynamic lubrication effects created by textured surfaces further contribute to friction reduction. By trapping lubricants within the micro-dimples, these surfaces maintain a stable coefficient of friction even under extreme conditions. This stability ensures consistent tribological behavior, improving the overall efficiency of tribological systems.

Improved Wear Resistance

Wear resistance is another critical tribological property enhanced by 3D texturing. Textured surfaces exhibit superior wear resistance compared to non-textured ones due to their ability to distribute stress more evenly. This distribution reduces localized wear and prevents the formation of cracks, extending the lifespan of components. For example, surface texturing in tribology has been shown to improve wear resistance through hydrodynamic effects, which reduce direct contact between surfaces.

Additionally, the application of laser processing techniques allows for precise control over surface roughness, further enhancing wear resistance. By reducing tool wear and extending tool life, 3D texturing addresses challenges associated with traditional surface finishing methods. This improvement leads to better tribological performance and more efficient production processes.

Enhanced Lubrication Efficiency

3D texturing optimizes lubrication efficiency by incorporating mechanisms that improve the distribution and retention of lubricants. Textured surfaces act as reservoirs, gradually releasing lubricants into the contact area during sliding. This process reduces the coefficient of friction and enhances wear resistance. The formation of a lubricating film on the surface also contributes to improved tribological characteristics, ensuring consistent performance over time.

Hydrodynamic lubrication plays a significant role in enhancing lubrication efficiency. The textures create a flow of lubricant that reduces friction and wear, particularly in high-load applications. These mechanisms make 3D texturing a valuable tool for improving the tribological behavior of metal surfaces, aligning with the demands of modern engineering.

Customization for Specific Needs

3D texturing offers unparalleled flexibility, allowing industries to tailor surface finishing to meet unique requirements. This customization enhances functionality, aesthetics, and performance across various applications. By adjusting texture patterns, depth, and density, manufacturers can create surfaces optimized for specific tasks.

Industries such as automotive and aerospace benefit significantly from this adaptability. In the automotive sector, 3D texturing enables the creation of realistic simulations for car interiors and exteriors. These high-fidelity textures accelerate design iterations and improve marketing efforts by providing immersive experiences. Companies like Tesla utilize advanced texture-mapping techniques to enhance virtual showrooms, offering customers a detailed preview of vehicles before production. Similarly, in aerospace, precise texturing improves the accuracy of digital assets, aiding decision-making and speeding up market entry.

The entertainment industry also showcases the creative potential of 3D texturing. Disney employs these techniques to craft lifelike environments in animated films. By blending technology with artistry, they achieve visually stunning results that captivate audiences. This demonstrates how 3D texturing extends beyond engineering, influencing fields where storytelling and design are paramount.

Customization through 3D texturing supports innovation by addressing specific challenges. For example, textured surfaces can improve grip in tools or reduce drag in aerodynamic designs. These tailored solutions enhance product performance while maintaining consistency in mass production. The ability to adapt surface finishing to diverse needs highlights the transformative potential of 3D texturing in modern manufacturing.

Tip: Industries can leverage 3D texturing to align product designs with both functional and aesthetic goals, ensuring competitive advantages in their respective markets.

Why 3D Texturing is the Future?

Advantages Over Traditional Methods

Precision and Consistency

3D texturing surpasses traditional surface finishing methods by offering unmatched precision and consistency. Advanced technologies like laser surface texturing allow manufacturers to create intricate patterns with exact specifications. This precision ensures uniformity across large-scale production, reducing variations that could impact performance. For example, in medical devices, surface textures enhance biocompatibility and chemical resistance, ensuring reliable results in surgical instruments and implants. Unlike traditional methods, which often struggle with irregularities, 3D texturing guarantees repeatable outcomes, making it indispensable in industries requiring high accuracy.

Long-Term Cost-Effectiveness

The long-term cost benefits of 3D texturing make it a preferred choice for modern manufacturing. By minimizing material waste and reducing tool wear, this technology lowers production costs. Additive manufacturing processes, which build objects layer by layer, significantly reduce scrap compared to subtractive methods. Additionally, the durability of textured surfaces extends the lifespan of components, decreasing maintenance expenses. Industries like automotive and aerospace benefit from these savings, as optimized surface texturing improves efficiency while reducing operational costs.

Potential for Innovation and Customization

3D texturing fosters innovation by enabling unparalleled customization. Manufacturers can tailor surface textures to meet specific needs, whether for improved grip, reduced friction, or enhanced aesthetics. This adaptability supports diverse applications, from ergonomic handles to aerodynamic designs. The technology also facilitates collaboration between designers and consumers, allowing for co-creation of unique products. For instance, high-quality textures improve communication during the design phase, reducing prototyping costs and accelerating market entry. This flexibility empowers industries to push creative boundaries while maintaining functionality.

Alignment with Sustainable Manufacturing Practices

Sustainability is a key advantage of 3D texturing. By using only the necessary amount of raw material, additive manufacturing minimizes waste, reducing production scrap by up to 90%. Energy-efficient 3D printers further contribute to sustainability by consuming less power during the process. Companies like Airbus and Ford have adopted 3D printing to produce lighter components and optimize designs, leading to lower emissions and energy consumption. These practices align with global efforts to reduce environmental impact, making 3D texturing a cornerstone of sustainable manufacturing.

Note: The integration of 3D texturing into industries like automotive, aerospace, and medical devices highlights its potential to revolutionize manufacturing while addressing environmental challenges.

Conclusion

3D texturing represents a groundbreaking shift in metal surface finish, offering transformative benefits for tribology. Its ability to reduce friction, enhance wear resistance, and optimize lubrication has redefined performance standards across industries. Companies like Tesla have leveraged this technology to refine vehicle simulations, improving design efficiency and customer engagement. Similarly, Disney has used advanced texturing to create lifelike environments in films such as Raya and the Last Dragon, blending realism with artistry. These examples highlight the versatility of 3D texturing in both engineering and creative fields.

As industries evolve, 3D texturing will continue to drive innovation and efficiency. Its precision, adaptability, and alignment with sustainable practices position it as a future-forward solution. By addressing challenges in tribology and enabling unparalleled customization, this technology ensures that manufacturers can meet the demands of modern applications while maintaining environmental responsibility.

Note: The integration of 3D texturing into diverse sectors underscores its potential to revolutionize manufacturing and design, making it an indispensable tool for the future.